When working with lasers, it’s essential to have effective laser fume extraction systems in place. These systems protect operators and the environment from hazardous fumes created during processes like laser marking, etching, and cutting. Choosing the right solution for your needs is vital for ensuring safety and efficiency. Here’s what to consider when selecting the ideal system.

Understand the Type of Laser Application

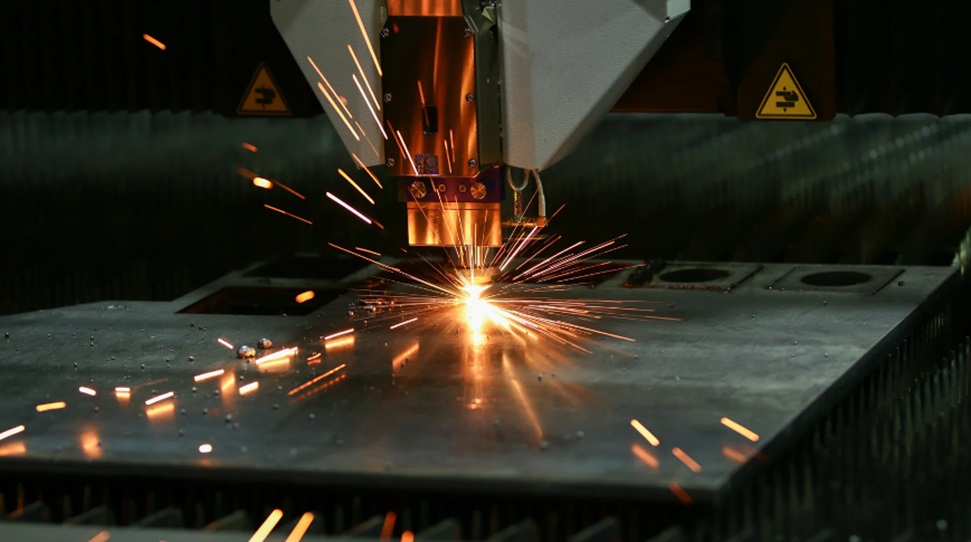

The type of laser operation you perform significantly impacts the kind of fume extraction system you’ll need. For instance, laser cutting and engraving produce different levels of particulates and fumes compared to processes like laser marking or welding. Each application emits unique byproducts that can pose health risks if improperly managed. It’s helpful to explore how laser dust and engraving fumes are considered potential health hazards, shedding light on why customized solutions are often necessary.

When evaluating your needs, take into account the specific materials and processes involved. Cutting plastics will release different toxins compared to engraving metals, so your extraction system must be tailored to handle these variations.

Evaluate the Extraction System’s Filtration Capabilities

Filtration is a critical element of any effective laser fume extraction system. These systems often use multiple stages of filters, such as HEPA filters for capturing fine particulates and activated carbon filters to neutralize harmful gases. Ensure the system has the capacity to match the level of filtration your applications demand.

The efficiency of these filters directly impacts air quality in the workspace. Regular maintenance of filters is crucial to maintain their performance. Following essential maintenance tips for laser fume extraction systems can help you extend the life and efficiency of your equipment, ensuring it continues to meet safety standards over time.

Consider System Mobility and Size

Workspaces come in different configurations, so consider whether a compact or mobile extraction system is more suitable for your setup. Smaller workshops may benefit from a portable system that can be moved wherever it’s needed. Conversely, large industrial operations might require a stationary unit capable of handling much higher fume volumes.

Assess your workspace layout and determine if a centralized system for your entire facility or independent units for specific machines would be more effective. Think about scalability, too—investing in a system that can grow with your operations might save you from costly upgrades later.

Analyze Cost and Energy Efficiency

While safety should always be the top priority, affordability, and energy efficiency are also key factors. Look for a system that minimizes long-term operational costs. Systems that consume less energy while maintaining high filtration performance are ideal, as they provide safety and a smaller environmental footprint.

It’s also important to evaluate the total cost of ownership. This includes the upfront purchase cost, maintenance expenses, and replacement filters. Cheaper systems might require more frequent repairs or replacements, negating any initial savings.

Prioritize Safety and Compliance

Laser fume extraction systems don’t just protect against immediate health risks; they also help businesses meet regulatory safety and environmental standards. Non-compliance can lead to hefty fines or reputational damage. Verify that the system you select is compliant with occupational health regulations, such as those mandated by OSHA or similar authorities in your region.

Additionally, opting for a system with fail-safes like audible alarms for clogged filters or system malfunction notifications can significantly improve workplace safety.

Choose a Reliable Manufacturer

Lastly, the manufacturer you choose plays a huge role in the quality and reliability of your laser fume extraction system. Partnering with trusted suppliers ensures you’re investing in proven technology backed by robust customer service. Look for companies with strong industry experience and a track record of delivering effective solutions.

Beyond the product, a reliable manufacturer offers professional advice, helping you match the right system to your specific needs. This relationship can also make routine maintenance and emergency repairs much more manageable.

Conclusion

Selecting the right laser fume extraction system involves weighing several critical factors, from the specific application requirements to the system’s filtration capacity, size, costs, and compliance with safety regulations. By understanding your laser processes and taking steps to evaluate these key elements, you can find the system that offers the best protection for your team and workspace. Don’t overlook the importance of regular upkeep and thoughtful planning when making your choice—a well-maintained and appropriate system is an investment in both health and productivity.